Reeled, Thrown, Spun, or Raw?

Terminology can be confusing, so I'll attempt to briefly describe what the various types of silk thread are all about.<\p>

Reeled (filament) silk - highest quality <\p>

The bombyx mori caterpillar makes its cocoon out of one single, very long, filament of silk, glued together with a natural gum called sericin.<\p>

|

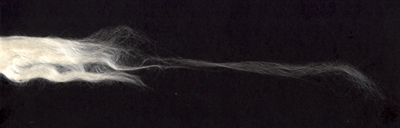

Reeling cocoons is essentially a matter of softening the sericin enough to locate the end of the filament, combining this filament with those of other cocoons, and winding off the resulting thread. As long as it has the sericin in it, it's called by various names - grege silk, gummed silk, or raw silk. It's rather stiff and springy, slightly creamy colored from the sericin, and reminds me of very fine fishing line, or hair. If the sericin is removed (usually in a solution of hot water, soap and soda) the filaments of silk become unglued from each other and are free to spread out. This is unthrown silk, or silk with no twist. Sometimes it's sold as stranded silk. When a more cohesive thread is needed, reeled silk can be twisted. Two or more twisted threads can then be combined and twisted again (or thrown) in the opposite direction to make plied thread (2 and 3 ply are most common). Reeled thread with a heavy twist is called organzine, a lighter twist is called tram. Because reeled silk is composed of VERY long filaments, it doesn't need to be twisted to hold it together. It's the presence of continuous filaments that determine whether it's reeled, NOT the presence of twist. |

Spun silk - most common <\p>

Waste from the reeling process, cocoons that weren't reelable, or cocoons from which the moth emerged are used for spun silk. It's degummed and then combed out into parallel fibers. To make it more manageable, the fibers are cut into shorter lengths and drawn out into a rope of parallel, overlapping fibers. From this point, it either continues on to be spun into thread by machine, or it's sold to handspinners.<\p>

Because spun silk is composed of short lengths of fiber (like wool or cotton), it MUST

have twist to

hold it together. The amount of twist, or number of plies is variable, and determines how hard or soft the thread feels. <\p>

Silk noil - waste of the waste <\p>

|

After the best cocoons are reeled, and the remaining silk is combed into a smooth preparation for spinning, there's still some waste left. These are the short, tangled bits that are bleached and carded to fluff them up. It's then spun, to produce a nubby, textured thread. Look out for black flecks - those are bits of pupae caught in the fiber! Some noil is better quality that others. Fabric made from silk noil is sometimes called raw silk - not to be confused with reeled silk that hasn't been degummed! Silk noil is pretty obvious by the texture, and definitely needs twist to hold it together. |

My favorite method for testing whether a thread is reeled or spun is to untwist several inches to see if it separates into filaments (reeled) or actually pulls apart (spun). You really can't tell just by looking at it.<\p>